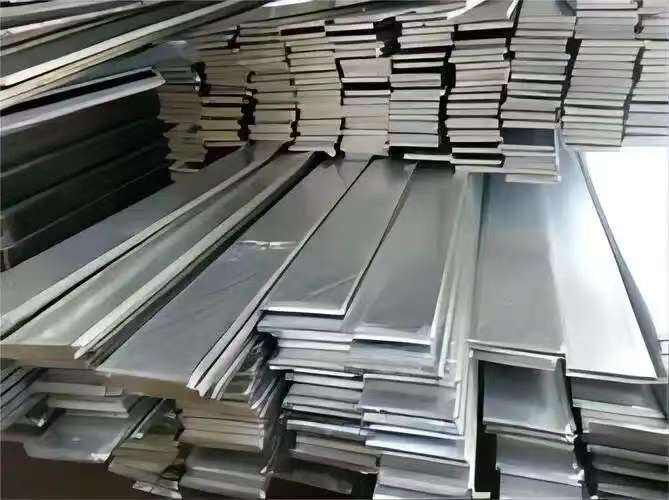

galvanized steel pipe manufacturers

Galvanized steel pipe manufacturers represent a crucial segment of the metal fabrication industry, specializing in producing high quality corrosion resistant piping solutions. These manufacturers employ advanced hot dip galvanization processes, where steel pipes are coated with a protective layer of zinc to enhance durability and longevity. The manufacturing process involves sophisticated quality control systems and automated production lines that ensure consistent product quality and dimensional accuracy. Modern manufacturers utilize state of the art equipment for zinc coating application, precise cutting, threading, and testing procedures. These facilities typically maintain extensive inventory systems and offer customization options to meet diverse client specifications. The pipes produced find extensive applications across various sectors, including construction, water supply systems, fire protection networks, and industrial processing. Manufacturers often provide comprehensive product ranges, from small diameter pipes for residential plumbing to large diameter pipes for industrial applications. Many leading manufacturers also invest in research and development to improve coating technologies, enhance production efficiency, and develop innovative solutions for emerging market needs. Their production capabilities typically include various pipe specifications, wall thicknesses, and coating options to serve different application requirements.