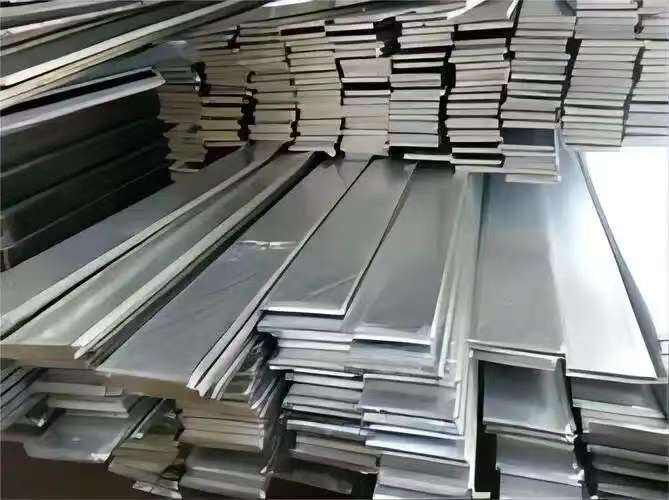

galvanized flat bar

Galvanized flat bar represents a crucial component in modern construction and manufacturing, combining structural strength with superior corrosion resistance. This versatile product undergoes a specialized hot-dip galvanization process, where steel bars are immersed in molten zinc at temperatures around 860°F (460°C), creating a metallurgically bonded protective coating. The resulting zinc layer not only shields the underlying steel from environmental elements but also provides sacrificial protection, meaning the zinc corrodes preferentially to protect the base metal. These flat bars are manufactured in various dimensions, typically ranging from 1/8 inch to 2 inches in thickness and 1/2 inch to 6 inches in width, offering flexibility for diverse applications. The galvanization process ensures uniform coating thickness and adherence to international standards for coating weight and quality. In industrial applications, these bars serve as essential components in structural support systems, electrical grounding networks, and mechanical assemblies. The combination of mechanical strength and corrosion resistance makes them particularly valuable in outdoor and marine environments, where exposure to harsh conditions demands superior material performance.