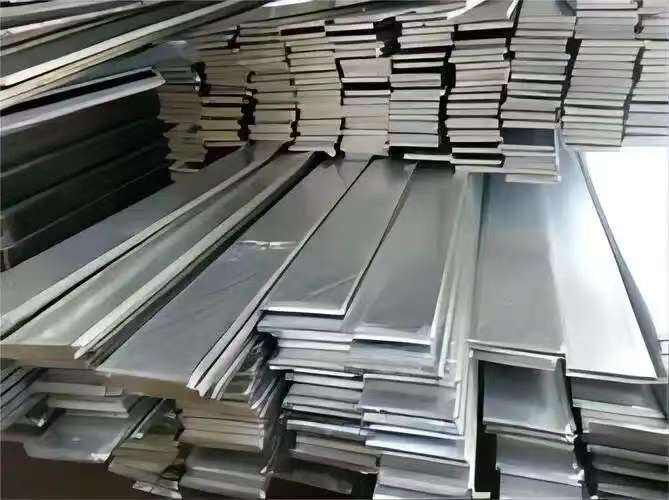

galvanized pipe manufacturers

Galvanized pipe manufacturers play a crucial role in producing essential components for various industries worldwide. These manufacturers specialize in creating steel pipes treated with a protective zinc coating through a hot-dip galvanization process, ensuring exceptional durability and corrosion resistance. The manufacturing process involves advanced technology and strict quality control measures, starting from selecting high-grade steel to the final galvanization stage. These facilities utilize state-of-the-art equipment and automated production lines to maintain consistent quality and meet international standards. Modern galvanized pipe manufacturers incorporate innovative features such as precise thickness control, automated welding systems, and advanced testing facilities to ensure product reliability. Their products find extensive applications in water supply systems, fire protection networks, structural supports, and industrial fluid transportation. The manufacturers typically offer various pipe sizes, ranging from small diameter tubes to large industrial pipes, catering to diverse customer requirements. Quality assurance processes include regular testing for zinc coating thickness, mechanical properties, and structural integrity, ensuring products meet or exceed industry standards like ASTM A53 and BS EN ISO 1461.