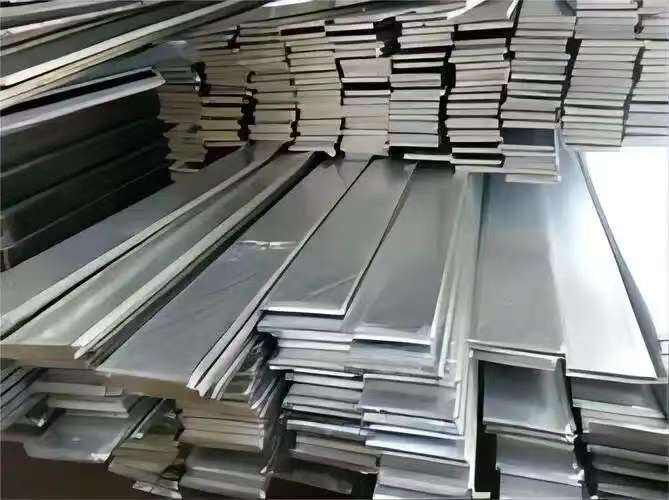

alloy steel plate

Alloy steel plate represents a sophisticated engineered material that combines the strength of steel with carefully selected alloying elements to enhance performance characteristics. This versatile material is manufactured through a precise process of combining iron with various elements such as chromium, nickel, molybdenum, and manganese, resulting in a product that exhibits superior mechanical properties compared to standard carbon steel. The plate's composition is carefully controlled to achieve specific strength, hardness, and durability requirements, making it ideal for demanding industrial applications. These plates are available in various thicknesses and dimensions, offering flexibility in manufacturing and construction processes. The material's enhanced properties include improved resistance to corrosion, better performance under extreme temperatures, and superior wear resistance. In industrial settings, alloy steel plates are fundamental components in heavy machinery, pressure vessels, and structural applications where standard steel would be insufficient. The manufacturing process involves careful heat treatment and cooling procedures to ensure uniform properties throughout the plate, resulting in consistent performance across the entire surface area. The material's versatility makes it particularly valuable in industries such as petroleum, chemical processing, power generation, and heavy construction, where reliability and durability are paramount considerations.