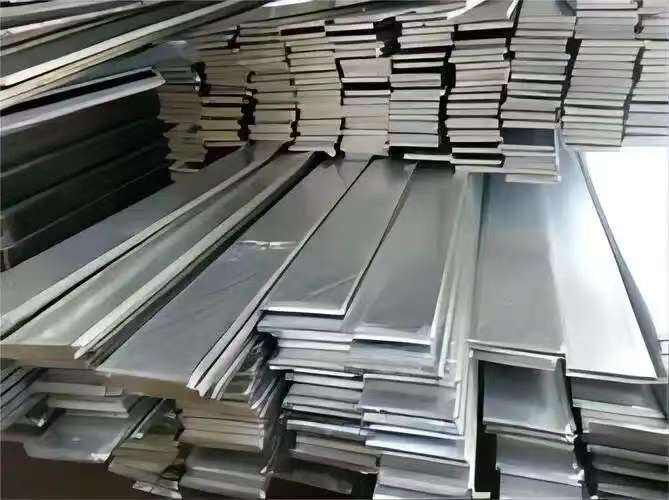

cold steel sheet

Cold steel sheet represents a fundamental material in modern manufacturing, produced through a sophisticated cold rolling process that transforms hot-rolled steel into thinner, stronger sheets with superior surface finish. This process reduces the thickness of steel while simultaneously improving its mechanical properties and dimensional accuracy. Cold steel sheets typically feature uniform thickness, excellent flatness, and enhanced strength-to-weight ratios. The manufacturing process involves passing the steel through a series of rollers at room temperature, which compresses and elongates the material, resulting in a harder, more durable product. These sheets exhibit remarkable versatility in terms of thickness ranges, typically available from 0.1mm to 3mm, making them suitable for various applications. The cold rolling process also imparts better formability and surface finish compared to hot-rolled alternatives, making cold steel sheets ideal for applications requiring precise dimensional tolerances and aesthetic appeal. The material's inherent characteristics include high tensile strength, improved wear resistance, and excellent paintability, contributing to its widespread use across multiple industries.