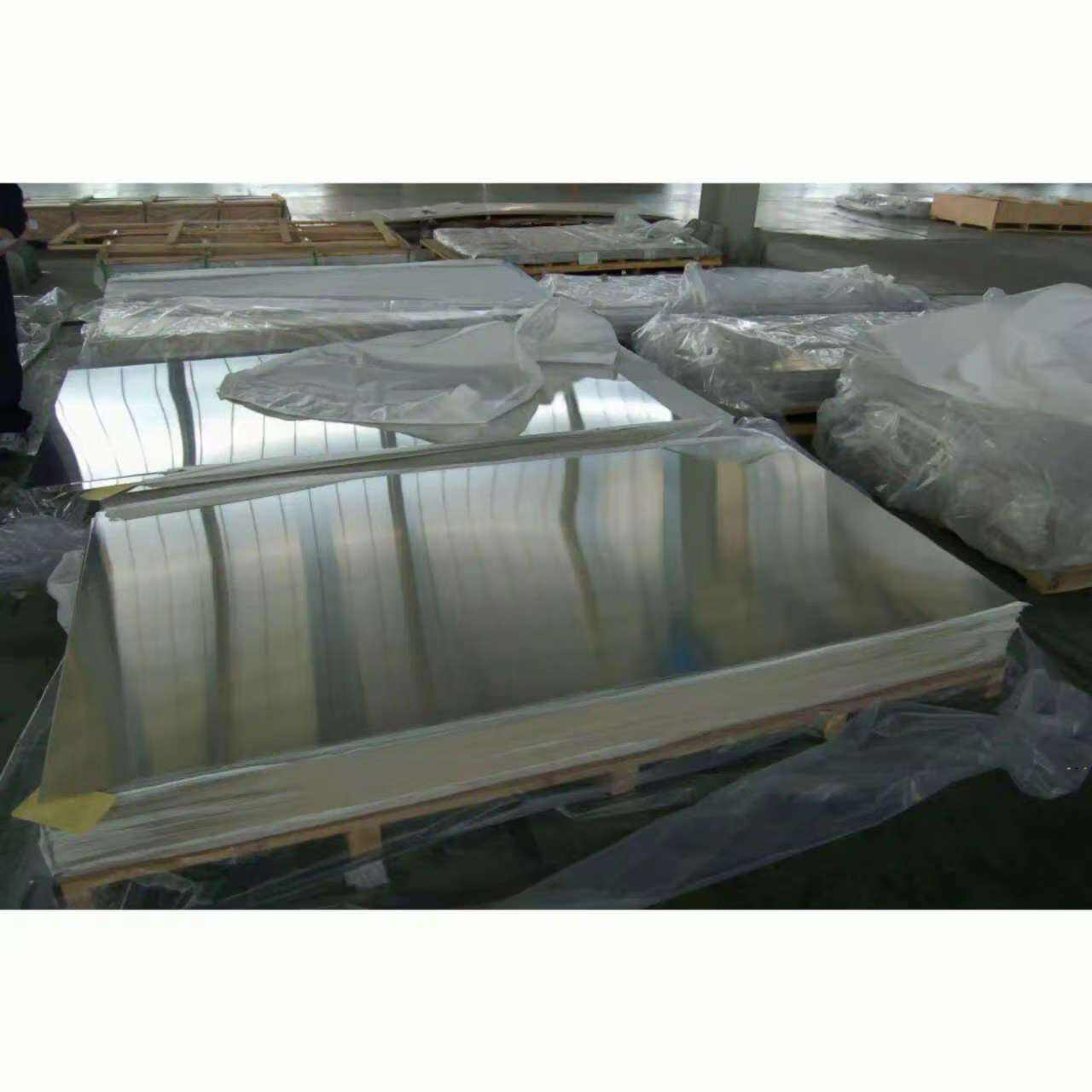

steel and alloy

Steel and alloy materials represent the backbone of modern industrial manufacturing and construction, combining strength, durability, and versatility in countless applications. These engineered materials consist of iron combined with various elements such as carbon, chromium, nickel, and manganese, creating compositions that exhibit enhanced properties beyond those of pure metals. The primary functions of steel and alloy materials include structural support in construction, component manufacturing in automotive and aerospace industries, and specialized applications in medical devices and energy infrastructure. Through advanced metallurgical processes, these materials can be customized to achieve specific mechanical properties, including high tensile strength, improved corrosion resistance, and enhanced thermal stability. Modern steel and alloy production employs sophisticated technologies such as vacuum degassing, continuous casting, and precision heat treatment to ensure consistent quality and performance. These materials play a crucial role in sustainable development, as they are highly recyclable and can be engineered to reduce material consumption while maintaining structural integrity. The versatility of steel and alloy materials extends to their ability to withstand extreme temperatures, resist wear and tear, and maintain dimensional stability under varying environmental conditions.