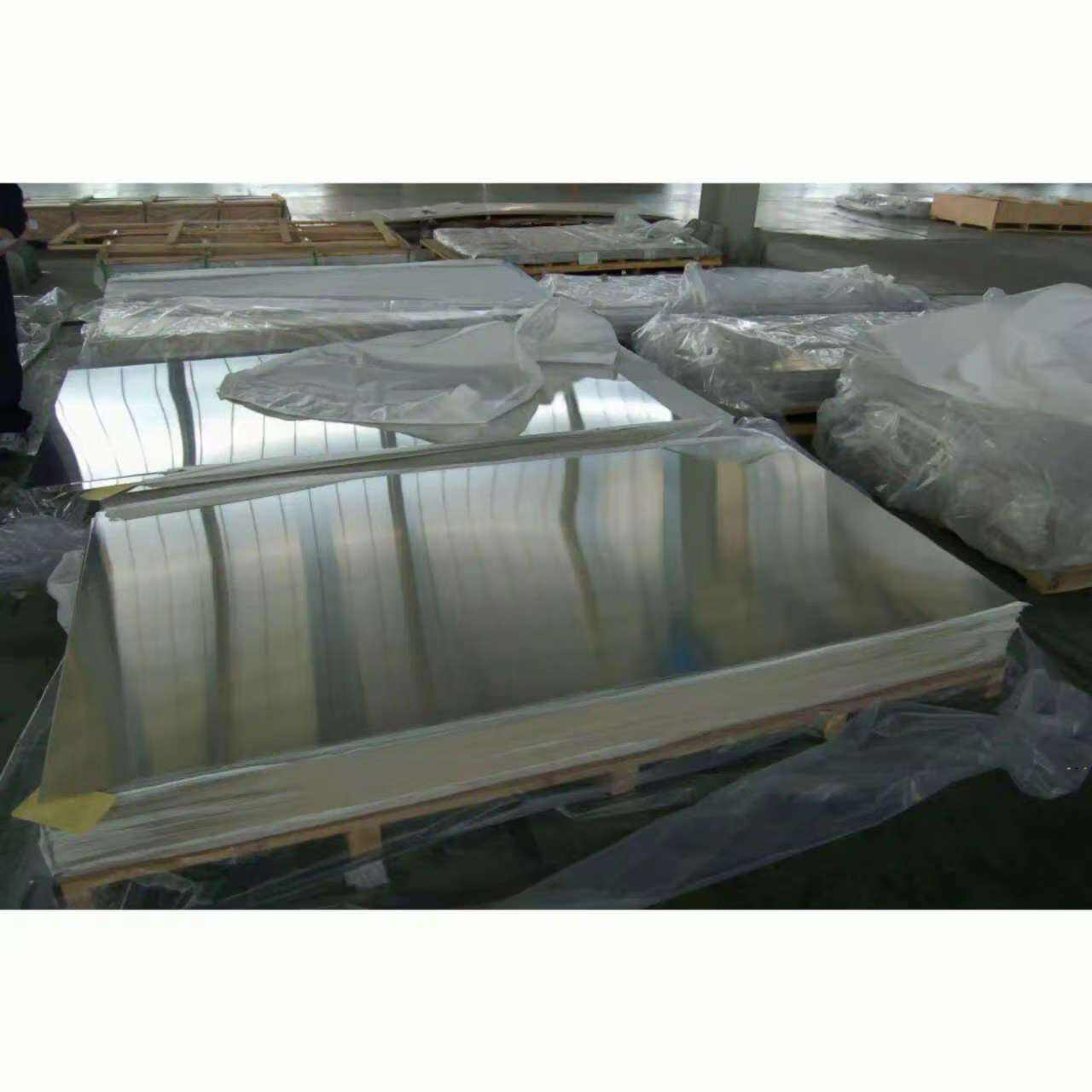

cold rolled corrugated steel

Cold rolled corrugated steel represents a sophisticated advancement in metal manufacturing, combining durability with versatility in modern construction applications. This specialized steel undergoes a precise cold rolling process at room temperature, resulting in superior dimensional accuracy and enhanced mechanical properties. The corrugated pattern, characterized by parallel ridges and valleys, significantly increases the material's structural strength while maintaining a relatively light weight. The manufacturing process involves passing flat steel sheets through a series of rollers that gradually form the distinctive wave-like pattern, creating a product that offers exceptional load-bearing capacity and spanning capabilities. The steel's surface typically features a protective coating, such as galvanization or paint systems, ensuring long-term resistance against corrosion and environmental factors. This material has become indispensable in various sectors, from industrial roofing and wall cladding to agricultural buildings and storage facilities. Its ability to withstand severe weather conditions while providing effective water drainage makes it particularly valuable in construction projects where durability and performance are paramount.